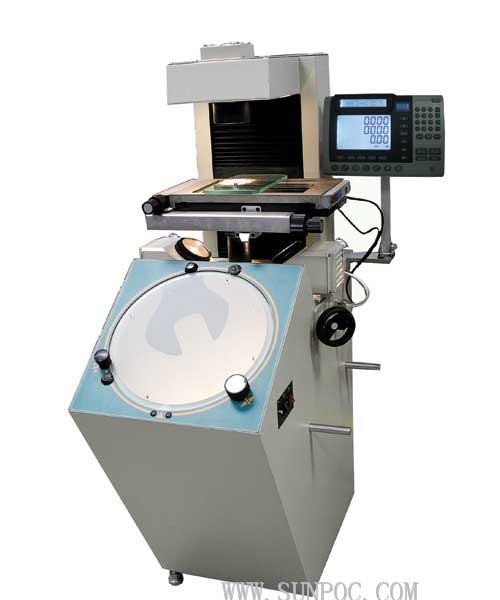

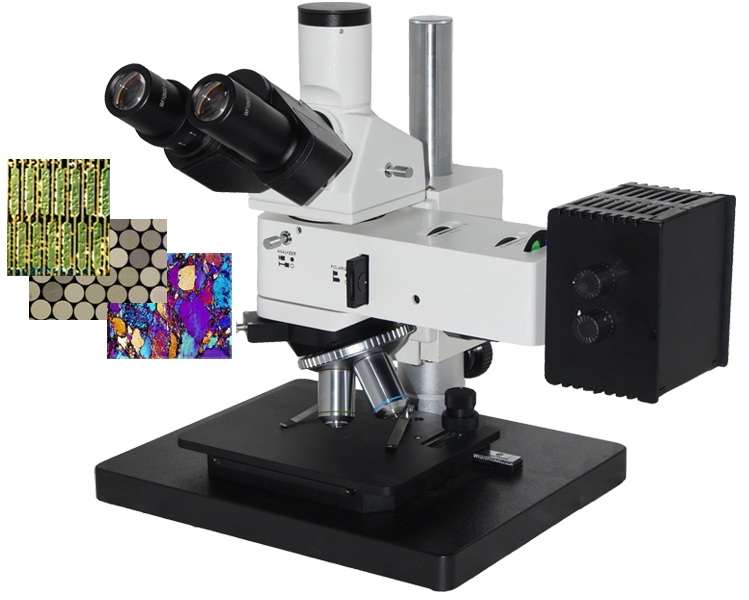

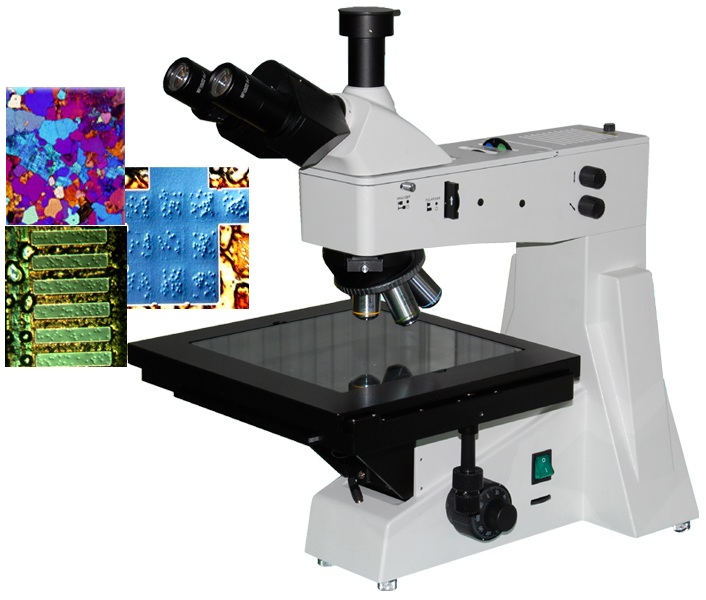

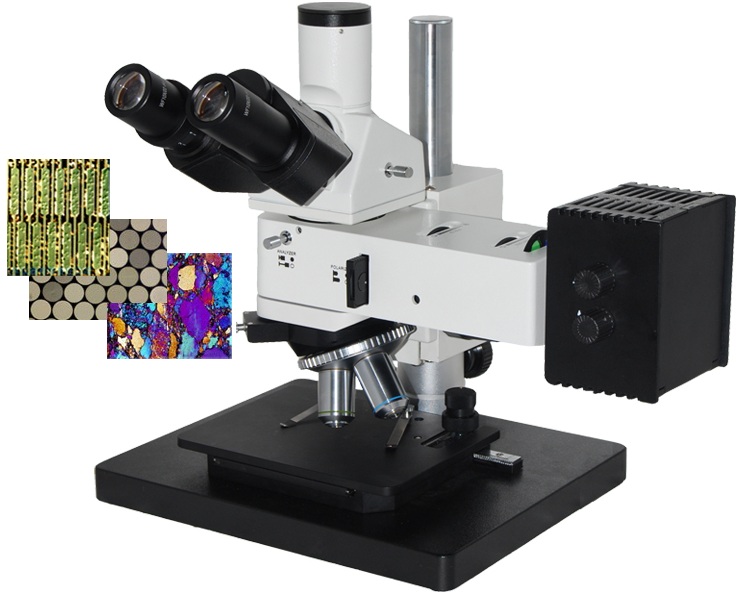

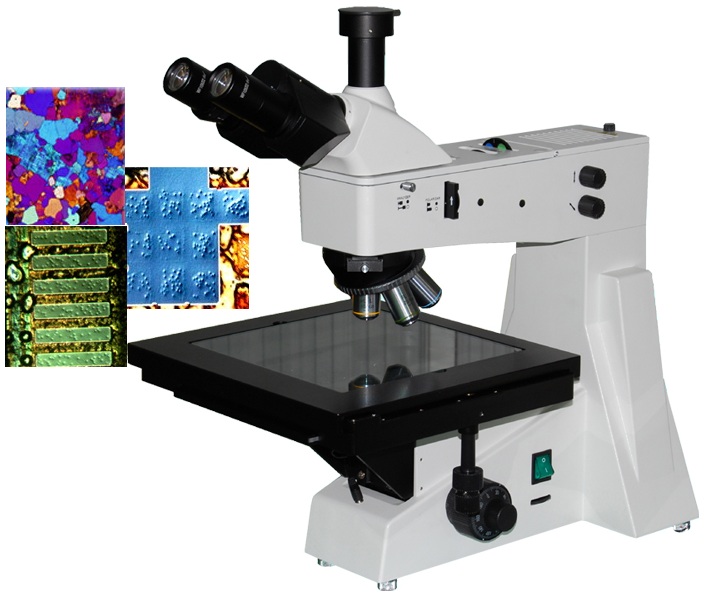

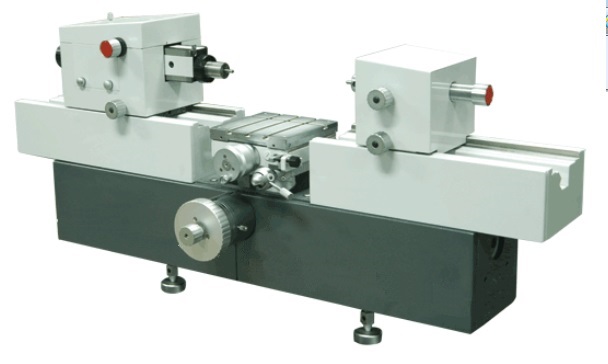

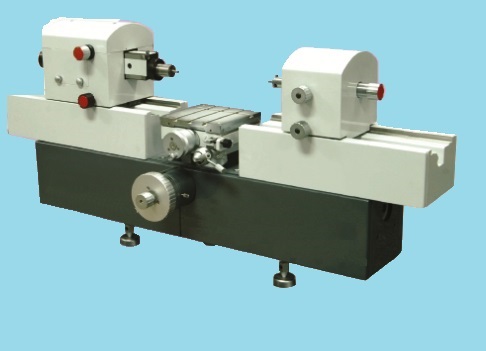

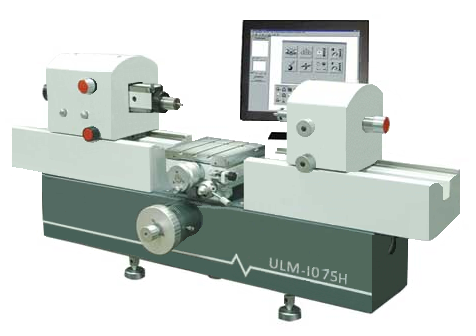

Universal Length Measuring Machine ULM-1067D

Brief Introductions:

Usages:

As the length metrological instrument, The Length Measuring Machine is for direct and differential measurements, it is mainly used in metal-working industry, especially the inspection department of those industries of machine manufacturing, measuring tool and gauges together with measuring instruments. It is the high-technology product of the integration of the optics, mechanic and electricity and adopts the grating displaying technology, which has greatly improved the accuracy and efficiency. At the same time, it various accessories have improves the universal performance. Its measuring parts are as follows:

a. Smooth cylindrical workpieces such as axis, hole, gauge and ring gauge

b. The pitch diameter of internal and external thread, thread gauge and thread ring gauge

c. Workingpiece with parallel plane surface, such as measuring rod and lower grades gauge.

Instrument Features:

Features:

* High-quality castings, under long-term natural aging treatment, are selected for the foundation, with fine stability

* Optimized square design is adopted for the spindle to assure the stability of its kinetic property under measurement

* Accessories with powerful and multiple functions may be selected to satisfy different requirement in measurement

* The infrared light-emitting component, with low voltage, small current, small volume and long life are adopted as the light source in the grating lighting system

* The high-precision measuring system is adopted for this instrument, which would be in conformity with the Abel Principle and with high precision in measurement

* ULM-1067D: The grating digital display technique is adopted, equipped with a digital display device,the measured value of length is displayed in figures, direct-viewing and convenient

Main Functions:

* Optimized square design is adopted for the spindle to assure the stability of its kinetic property under measurement

* Accessories with powerful and multiple functions may be selected to satisfy different requirement in measurement

* The infrared light-emitting component, with low voltage, small current, small volume and long life are adopted as the light source in the grating lighting system

* The high-precision measuring system is adopted for this instrument, which would be in conformity with the Abel Principle and with high precision in measurement

* ULM-1067D: The grating digital display technique is adopted, equipped with a digital display device,the measured value of length is displayed in figures, direct-viewing and convenient

Main Functions:

1. Absolute measurement and comparison measurement for the external dimension

2. Internal dimension measurement

3. Measuring accuracy for the internal and external dimension

4. Measuring the internal and external threads

5. Segment compensation for the grating value, linear compensation for the grating value, temperature compensation

6. Input date and modify data by keyboard, delete coordinate point

7. Open documents and save coordinate point

8. Grating data imaging and finding reversal point

9. The measuring results import Excel and Print measuring results.

Technical Specifications

Technical parameters:

Measuring range (mm):

1.External dimension: a. Absolute measurement 0~100

b. Relative measurement 0~670

1.External dimension: a. Absolute measurement 0~100

b. Relative measurement 0~670

2. Operating model: by mouse

3. Internal dimension measurement:

a. With small measuring yokes (depth of penetration up to 12mm, maximum wall thickness 50mm)10~400

b. With large measuring yokes (depth of penetration up to 50mm, maximum wall thickness 85mm)30~370

a. With small measuring yokes (depth of penetration up to 12mm, maximum wall thickness 50mm)10~400

b. With large measuring yokes (depth of penetration up to 50mm, maximum wall thickness 85mm)30~370

c. With electric equipment with electric measuring yoke 1-60mm

d. With universal measuring yoke:14-112mm

4. Measuring the internal pitch diameter:

4. Measuring the internal pitch diameter:

a. With small measuring yoke (thread small diameter) 13~30mm

b. With large measuring yoke{thread small diameter) 31-(70-wall thickness)X2}

b. With large measuring yoke{thread small diameter) 31-(70-wall thickness)X2}

Pitch of screws 0.5~6

5. Measuring the external pitch diameter: Maximum value 200

Pitch of screw:1~6

6. Accuracy of the instrument In case of temperature: (20℃±0.2℃):

External direct measurement : (0.5+L/200)μm

Internal measurement superior to: (1.0+L/100)μm

External direct measurement : (0.5+L/200)μm

Internal measurement superior to: (1.0+L/100)μm

7.Reading model and displaying value:

Digital display, the value is 0.1um

8. Measuring force: 0, 1.5, 2.5N

9. Variability of the displaying value

a. External measurement 2σ ≤0.3μm

b. Internal measurement 2σ ≤0.5μm

a. External measurement 2σ ≤0.3μm

b. Internal measurement 2σ ≤0.5μm

10. Universal worktable :

Mounting area Approximately (160×160) mm

Adjusting range of height (0~100) mm

Transverse travel 25mm

Tilting rage around Y axis ±3°

Worktable rotation ±4°

Load capacity 10kg

Mounting area Approximately (160×160) mm

Adjusting range of height (0~100) mm

Transverse travel 25mm

Tilting rage around Y axis ±3°

Worktable rotation ±4°

Load capacity 10kg

11. Fitting size for the measuring cap’s internal diameter : Φ6H7

12. Size of outer diameter between the reference rod and the measuring cap’s internal diameter : Φ6g6

13. Instrument dimension (mm): L×W×H 960×390×450

14. Net weight for the instrument: 150kg

Main Usage of Accessories:

1. Universal measuring yoke and its accessory is used to measure the external micrometer

a. 4mm spherical contacting head

b. 12mm spherical contacting head

c. 100mm contacting head of pin

2. Inclined fixed bracket: used to measure the external micrometer

3. Electric device: used to measure internal sizes

4. Center cradle: used to support the workpiece with center hole

5. Elastic measuring yoke: used to internal dimension measurement

6. Measure the hole diameter using small yoke: 13.5-26.5mm, depth: 15mm

7. Measure the hole diameter using large yoke: 26.5-200mm, depth: 50mm

8. Cross fixed bracket: used to put workpiece

9. Double V-shape bracket: measure the rod and internal micrometer

10. Single V-shape bracket: measure the rod and internal micrometer

11. Gauge combined bracket: used to mount gauge and rod

12. Floating workable: measure the spherical, thread and ring gauge

13.Contact tip: used to measure the external dimension of workpiece

Universal Length Measuring Machine ULM-1067D

Universal Length Measuring Machine ULM-1067D