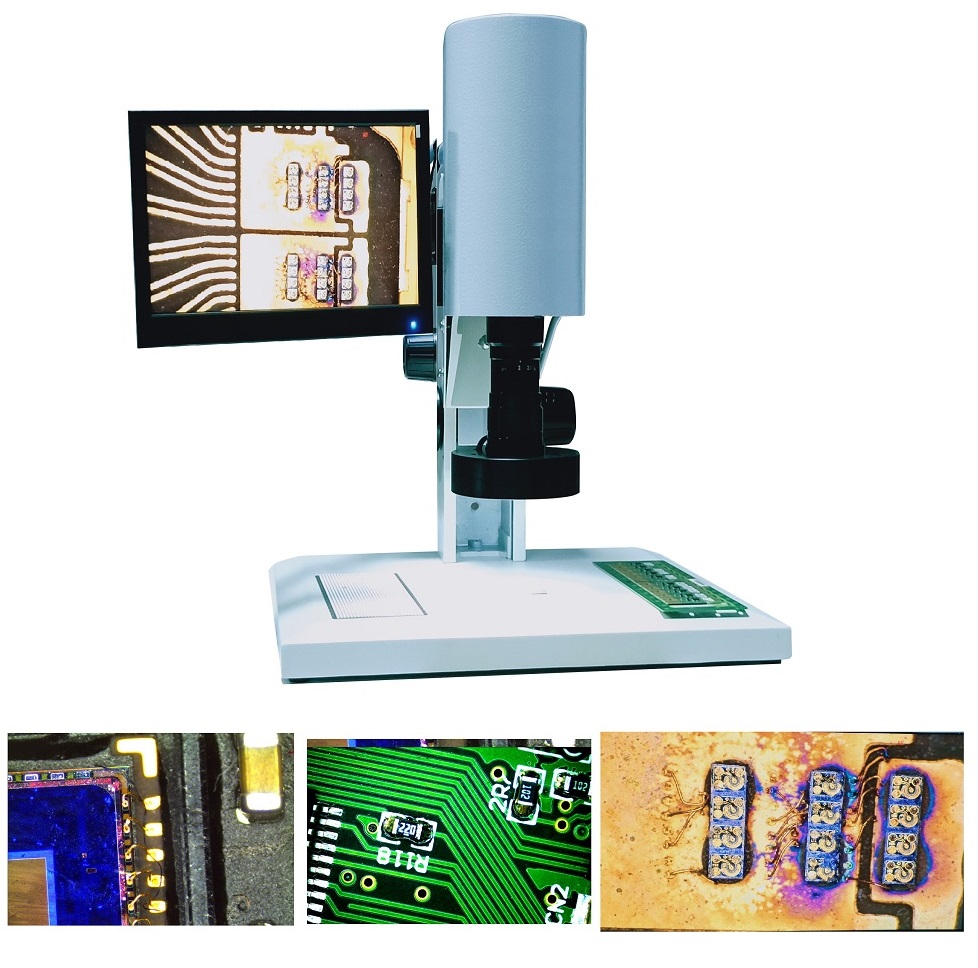

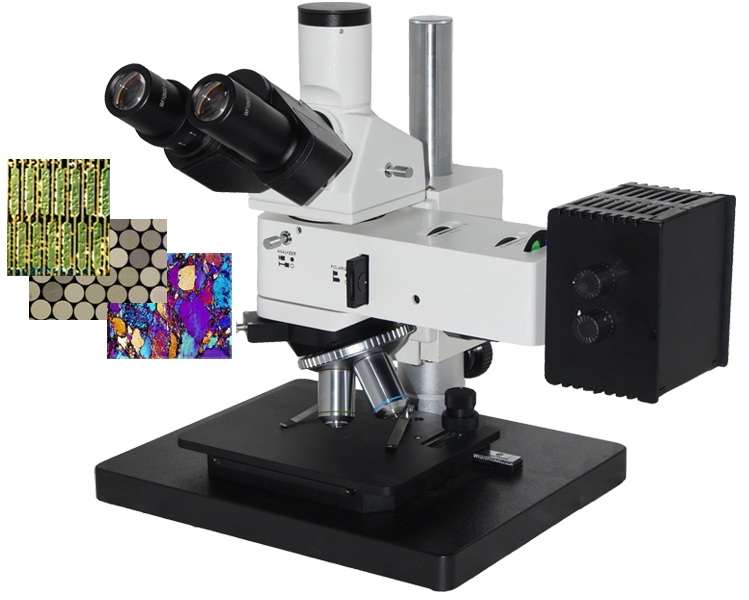

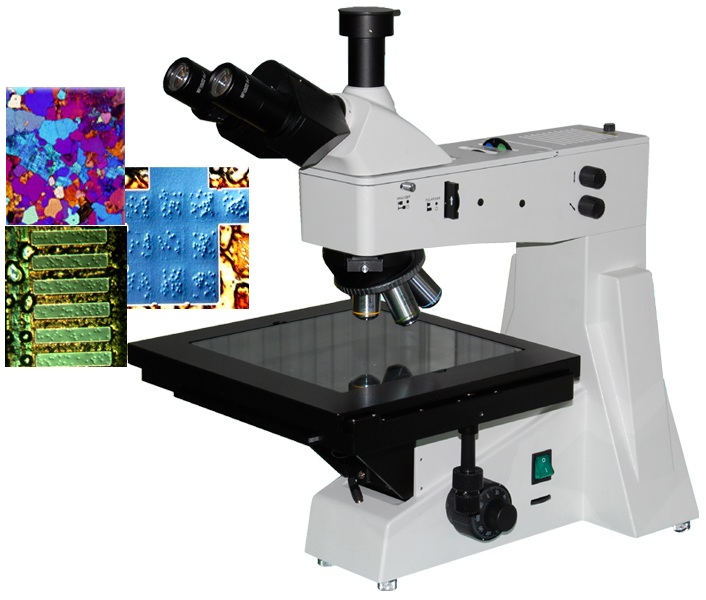

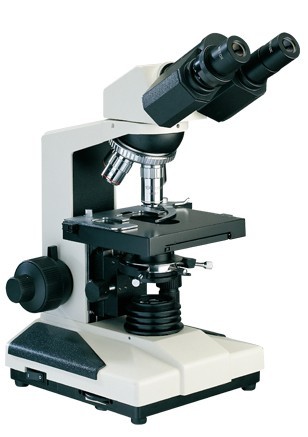

SZDA0745C High-contrasted Coaxial Illumination Zoom Monocular Video microscope systems

Brief Introductions:

SZDA0745C, original imaging and illumination optical system design, making it have higher contrast and depth of field. It can connect with CS-mount or C-mount CCD (CMOS) camera, display, computer etc. They can be used in electric equipments, semiconductor, LCD, LED etc. for observing, checking-up and survey digital images. Specially fit for checking-up objects with low reflectivity (such as plane presswork, LCD bugs).

Instrument Features:

Main data:◇ High-contrasted, in focus all the zoom course, even illumination

◇ Zoom objective magnification: 0.7X~4.5X. Working distance is 103mm.

◇ Standard total optical magnification: 0.7X~4.5X, extend total magnification: 0.15X~18X

◇ Adjustable high luminance LED coaxial illumination, AC100~240V, breadth voltage input.

◇ The measurement to match between the support and the main body is Φ45mm

◇ 0.3X, 0.5X, 1X(standard outfits), 1.5X, 2X five magnification CS-mount CCD adapter to be selected

◇ 0.7X, 2X auxiliary objective

Technical Specifications

Main optical data:

|

Auxiliary objective |

CCD adapter | |||||

|

0.3X |

0.5X |

1X |

1.5X |

2X | ||

|

Main body (Without auxiliary objective) |

Optical magnification |

0.21X~1.35X |

0.35X~2.25X |

0.7X~4.5X |

1.05X~6.75X |

1.4X~9X |

|

Field of video |

17.14X22.86~2.67X3.56 |

10.29X13.71~1.6X2.13 |

5.14X6.860.8X1.07 |

3.43X4.57~0.53X0.71 |

2.57X3.43~0.4X0.53 | |

|

Working distance(mm): 103 | ||||||

|

0.7X |

Optical magnification |

0.147X~0.945X |

0.245X~1.575X |

0.49X~3.15X |

0.735X~4.725X |

0.98X~6.3X |

|

Field of video |

24.49X32.65~3.81X5.08 |

14.69X19.59~2.29 X3.05 |

7.35X9.8~1.14X1.52 |

4.9X6.53~0.7X1.02 |

3.67X4.9~0.57X0.76 | |

|

Working distance(mm): 145 | ||||||

|

2X |

Optical magnification |

0.42X~2.7X |

0.7X~4.5X |

1.4X~9X |

2.1X~13.5X |

2.8X~18X |

|

Field of video |

8.57X11.43~1.33X1.78 |

5.14X6.86~0.8X1.07 |

2.57X3.43~0.4X0.53 |

1.71X2.29~0.27X0.36 |

1.29X1.71~0.2X0.27 | |

|

Working distance(mm): 35 | ||||||

|

Magnification range of zoom body 0.7X~4.5X | ||||||

|

Note: a. The field of video is based on 1/3" CCD adapter. b. Total magnification = Optical magnification × Digital magnification Optical magnification = CCD adapter magnification × Auxiliary objective magnification × Zoom body magnification Digital magnification = The size of display screen diagonal ÷ The size of CCD camera plate diagonal | ||||||

Main advantages:

its high contract and high definition are the same level to the other international similar competitive grade, but price is just 50% -70% of those products. It can see including LCD, chips, wafer etc. almost the whole objects.

its high contract and high definition are the same level to the other international similar competitive grade, but price is just 50% -70% of those products. It can see including LCD, chips, wafer etc. almost the whole objects.

Main sphere of application:

it uses to observe, analysis and checking-up wafer fab, chips, LCD etc fine test with high reflectivity and generic objects high clearly imaging observing, analyses. Especially fit for the high level research.

it uses to observe, analysis and checking-up wafer fab, chips, LCD etc fine test with high reflectivity and generic objects high clearly imaging observing, analyses. Especially fit for the high level research.

Adjusting explanation:

Loosen two screws above the Holder, the CCD attachment may revolve 360°so as to adjust the direction of CCD; meanwhile loosen three screws of the annular knurl part, and revolved the annular knurl part, it can adjust the high and low on focus. The top three screws can be adjusted when the CCD target surface isn’t in the central.

Loosen two screws above the Holder, the CCD attachment may revolve 360°so as to adjust the direction of CCD; meanwhile loosen three screws of the annular knurl part, and revolved the annular knurl part, it can adjust the high and low on focus. The top three screws can be adjusted when the CCD target surface isn’t in the central.

Optional attachments:

◇ CCD adapter, Digital camera junction and Photo adapter: TC0.5、C1.0 CCDT adapter,DT01、PT01T

◇ 1X stage micrometer CCD adapter: CDM1.0

◇ Eyepieces: 10X,15X,20X,30X;divisional eyepieces: 10X,15X,20X

◇ Stage micrometer: CDM0.01

◇ Auxiliary objective: 0.7X,2X

◇ Mechanical stage: S10086

|

|

Model: 0.3X, 0.5X, 1X, 1.5X, 2X CCD adapters Introduction: Selecting different magnification CCD adapters can change the total magnification of SZDA0745C high-contrasted coaxial illumination zoom monocular video microscope systems. We can select it according to the magnification. |

|

|

Model: CDM1.0 1X stage micrometer CCD adapter Introduction: Having 0.1mm/scale cross stage micrometer, cross stage micrometer and the image show in display at the same time, can do length measure directly. It can do precise length measure using software. Install: Twist this part to screw thread on top of CCD adapter, and directly twist CCD camera to C-mount top of this part. |

|

Model:0.7X, 2X auxiliary objectives Introduction: Connect the auxiliary objective under the SZDA0745C high contrasted coaxial illumination zoom monocular video microscope systems, can change the total magnification and the working distance. Users can select it according to the magnification and working distance. Working distance: DA-W0.7: 145mm; DA-W2.0: 35mm | |

|

Model: S10086 Mechanical stage Introduction: ◇ Put the object on the mechanical stage for expediently moving specimen in XY directions, easily finding images. ◇ The moving range of X direction 100 mm ◇ The moving range of Y direction 86 mm |

SZDA0745C High-contrasted Coaxial Illumination Zoom Monocular Video microscope systems

SZDA0745C High-contrasted Coaxial Illumination Zoom Monocular Video microscope systems